Note: As with all of the content on this website, you can simply click on any picture to get its largest size. In this way, we can maintain the clearest definition to make it easier for you to see the detail. If the picture is so big you can't see all of it on your screen, all you have to do is hold down CONTROL and move the mouse wheel up and down to resize!

This procedure was done in the frame off configuration. It would be very difficult to do this on a complete truck due to the fire hazard. Observe all safety precautions and use common sense.

First off, the good news. It’s not all that hard! The hardest part of this entire thing was getting good information to figure out where to begin. Different procedures, different opinions abound. So after a very large amount of research, asking seemingly stupid questions on various forums, this is what actually works! I do not give website links in this procedure because they change. Do the appropriate Google Search! Where the opinions vary is a lot of the old timers used the boiler rivet method where you heat the whole rivet red hot, insert it in the hole and with a bucker (person) on one end holding a very heavy bucking bar, the other one hammers the rivet home. They insist this is the only way to get the proper heat throughout the rivet. I contend, after researching this, that by the time you have put the tongs on the hot rivet, pushed it in the hole, put the bar against it solidly you have cooled the head down sufficiently to the point where you might as well have just heated the rivet in the hole. The problem of heat shunting out due to the surrounding metal and bucking bar being cold IS a real problem. Maybe that’s why our friends at Chevy used hydraulic riveters and set them completely cold. I feel you can do it better because the rivet will tighten more as it cools.

First off, the good news. It’s not all that hard! The hardest part of this entire thing was getting good information to figure out where to begin. Different procedures, different opinions abound. So after a very large amount of research, asking seemingly stupid questions on various forums, this is what actually works! I do not give website links in this procedure because they change. Do the appropriate Google Search! Where the opinions vary is a lot of the old timers used the boiler rivet method where you heat the whole rivet red hot, insert it in the hole and with a bucker (person) on one end holding a very heavy bucking bar, the other one hammers the rivet home. They insist this is the only way to get the proper heat throughout the rivet. I contend, after researching this, that by the time you have put the tongs on the hot rivet, pushed it in the hole, put the bar against it solidly you have cooled the head down sufficiently to the point where you might as well have just heated the rivet in the hole. The problem of heat shunting out due to the surrounding metal and bucking bar being cold IS a real problem. Maybe that’s why our friends at Chevy used hydraulic riveters and set them completely cold. I feel you can do it better because the rivet will tighten more as it cools.

What you need:

What you need:

At least a 4x Air Chisel/ Hammer. I used one with a .401 hole to accept the readily available rivet setter. I had one sitting in a drawer so didn't have to go out and buy one, but if you don't have one, get a good Ingersol or Chicago Pneumatic while you are at it. They make chisels for these units that very nicely cut sheet metal so there are other applications (excuses) for having this around the shop.

An 11/16” Rivet Setter with the .401 shank. This is what does the shaping of the squashed rivet to make it look like factory. They are around $30 each. The one you need for most of the rivets on this frame is the 11/16” round head version made for a 3/8” rivet. I got mine from Byler Rivet. The part number was SM50 430-12.

An OxyAcetylene Torch with a #4 Medium Rosebud (Heating) Tip.I didn't have this at all, So more research told me to get a Victor Setup. NOT a Victor STYLE, TYPE setup. In other words, no chinese knockoffs here. Its worth the extra money to get the appropriate gear. The Victor Performer Edge Medium Duty Kit cost $230 on Amazon and the regulators and everything are excellent quality. If you are a noob, you will also need bottles. Your local welding supply can provide them at reasonable cost. Don’t play with fire! Get good OA Torch equipment because of the fire hazard and possible leakage from inferior tooling.

An OxyAcetylene Torch with a #4 Medium Rosebud (Heating) Tip.I didn't have this at all, So more research told me to get a Victor Setup. NOT a Victor STYLE, TYPE setup. In other words, no chinese knockoffs here. Its worth the extra money to get the appropriate gear. The Victor Performer Edge Medium Duty Kit cost $230 on Amazon and the regulators and everything are excellent quality. If you are a noob, you will also need bottles. Your local welding supply can provide them at reasonable cost. Don’t play with fire! Get good OA Torch equipment because of the fire hazard and possible leakage from inferior tooling.

1-1/8 Inch Long, 3/8” shank diameter, Round Head, Steel Rivets.I got my rivets from Jay-Cee Rivets. 100 of them cost about $15. (Smallest quantity they sell). For those who are wondering why 1-1/8” long... I chose to get 100 of the same size and then cut them down to the appropriate size after I got them. The longest application is when you are riveting the front leaf spring mounts together with the rear engine crossmember. The rule for the length you need is 1.5 times the shank size sticking out of the hole. So you have a 3/8” rivet, you want the thickness of what you are riveting plus 3/8” plus 3/16” (half of the 3/8”) or to make a long story short, 9/16” sticking out of the hole. This works flawlessly and provides a very factory looking rivet. The part number was S0375R01125.

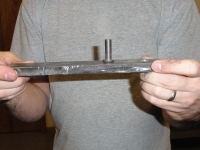

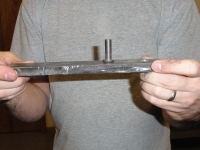

Bucking Bars. Go to your local welder and ask for scraps of 1/2” thick steel. You want the dimensions to vary but I used 1-1/2” by 8 inch for most of the job and a 2” by 10 inch for the rest. Read the rest of this procedure before doing this so you understand the concept first. You will be clamping this bar in place to hold the rivet, so you will also need to drill a 9/16” concave into the steel where the rivet will be placed. Put the bar against the hole and mark the hole, then drill the hole. Make the hole ONLY deep enough to complete a full circle with the tip of the drill bit. You just need a very slight but complete concavity.

Bucking Bars. Go to your local welder and ask for scraps of 1/2” thick steel. You want the dimensions to vary but I used 1-1/2” by 8 inch for most of the job and a 2” by 10 inch for the rest. Read the rest of this procedure before doing this so you understand the concept first. You will be clamping this bar in place to hold the rivet, so you will also need to drill a 9/16” concave into the steel where the rivet will be placed. Put the bar against the hole and mark the hole, then drill the hole. Make the hole ONLY deep enough to complete a full circle with the tip of the drill bit. You just need a very slight but complete concavity.

Anything more will change the appearance of the rivet head when finished. Another contributor pointed out that the entire rivet head is about 11/16 and if you shape that hole a little bigger and a little deeper you won’t have as much of a problem with the C-Clamps failing. Don’t make the hole too deep or the rivet won't tighten down. Also, the reason I chose 1/2” steel is because of some of the tight places, but if you can get thicker steel, the more mass the easier it will be on the clamps.

C-Clamps. Use very beefy, very stout large C-Clamps for this. The biggest problem you are going to have is keeping that bar in place when hammering, so go overboard and get a few good Bessey welding clamps if you can afford it. Vise grip types will not do, cheap woodworking clamps won’t do. The Bessey 4800S or 7200S is good, but very expensive. If they are too pricey, just use really good C-Clamps and hope for the best.

C-Clamps. Use very beefy, very stout large C-Clamps for this. The biggest problem you are going to have is keeping that bar in place when hammering, so go overboard and get a few good Bessey welding clamps if you can afford it. Vise grip types will not do, cheap woodworking clamps won’t do. The Bessey 4800S or 7200S is good, but very expensive. If they are too pricey, just use really good C-Clamps and hope for the best.

Some Way to Cut Your Rivets. I use a DeWalt Porta-Band with the Swag Offroad Table. I drilled a 3/8” hole in a stick that was approximately the thickness of the shortest rivet, then used washers as shown to adjust the depth. A clean hole is very important to the end result as well. Make sure there is no paint, rust, crud inside or near the hole.

Now for the fun part!

Make sure you have a pretty nice fit by placing the rivet in the hole just to check that its not binding, or too loose. A 1/32” or so looseness is fine, but in my case, someone torched the old rivets out and ruined the holes, so I had to go in and weld them shut and re-drill them. Don’t expect the rivets to be very tight in the hole. The procedure will squash them very nicely to the proper size. For these vintage frames, the 3/8” rivet is the most popular.

Step 1: Place the rivet, cut to the appropriate length as previously mentioned, into the hole. You can grab it with a pair of visegrips so it will stay there. You are placing the head in the most inaccessible place pointing outwards where you can get the hammer its best chance at a straight shot. You can’t come at this at an angle at all!

Step 2: Place your custom bucking bar over the head of the rivet and very securely clamp into place. The clamps shown are not good enough for this job but it was all I had. Later, after fighting the problem of them falling off, I went to the heavier duty clamps. These DO work, but not consistently. I can’t express enough the importance of a good clamp. The hammer hits with such force that what you THINK is tight enough, probably isn’t.

Step 3: Ensure you have the secured rivet sticking straight out of the hole and not at an angle. Once it is straight and very secure...

Step 4: Insert the Rivet Setter into the air hammer, connect it to a normal 90-125psi air supply and just pretend you are going to use it to ensure there are no obstacles in your way. You want a totally unobstructed means to hammer the rivet home and the rivet setter must be totally straight to get a nice rivet head. Once you are sure you can push the rivet straight... Note: While I can see one person doing this, it is nice to have two people. The reason being, one person heats the rivet and pulls the torch away, turns it off, etc, while the other hammers the rivet. The heat doesn't last long enough to heat, then mess around with turning off the torch and setting it down, pick up the gun and rivet. If you had some sort of torch stand that you could just quickly set it on, maybe one person could do it. Get a friend to help you. Its just safer that way.

Step 5: Fire up the Acetylene Torch and heat the rivet shank EVENLY. Go around the diameter a few times and sort of at the base of the rivet with the idea of getting the shaft as hot at the base as possible. I was lucky since my friend Gene is also the town blacksmith he knew how hot to get the rivets before they melted. They should be glowing red hot and not just a little. If they start to turn white, back off. You need all the heat that rivet can stand.

Apply heat as close to the rivet head and base as possible as well as the entire shaft for best results. By the way, you can’t be reading this and doing the procedure at the same time! You simply don’t have time! It takes about 10-15 seconds to heat the rivet.

Apply heat as close to the rivet head and base as possible as well as the entire shaft for best results. By the way, you can’t be reading this and doing the procedure at the same time! You simply don’t have time! It takes about 10-15 seconds to heat the rivet.

Step 6: Speed is of the essence here. If you are a slow person, get someone else to do this. My friend Gene heated up the rivet, I stood right there beside the work with both hands on the gun and the very second he took the torch away, I hammered the rivet down. So be sure to have your rivet gun ready and place the rivet setter very squarely on the top of the red hot rivet and pull the trigger while pushing down. Push hard and straight until the rivet setting tool is almost completely against the frame. This takes about 2 seconds. Everything happens really fast.

Step 6: Speed is of the essence here. If you are a slow person, get someone else to do this. My friend Gene heated up the rivet, I stood right there beside the work with both hands on the gun and the very second he took the torch away, I hammered the rivet down. So be sure to have your rivet gun ready and place the rivet setter very squarely on the top of the red hot rivet and pull the trigger while pushing down. Push hard and straight until the rivet setting tool is almost completely against the frame. This takes about 2 seconds. Everything happens really fast.

Step 7: Admire your work. My first attempt was perfect and the rivet looked amazing. My second attempt wasn't so pretty so I had to grind off the rivet head and start all over. This turned out to be very revealing anyway. There is some controversy about this procedure shunting all the heat into the bucking bar thus making for a less secure rivet. I assure you this isn’t the case. On close examination of the cross section, all of the hole was completely filled and it took a very large punch and a very big hammer to knock it out of the hole. Due to the properties of steel, heating a rivet, squashing it in the hole, then letting it cool makes for an extra tight fit since heat expands when hot and contracts when cool.

At this point all that’s left is cleaning around the rivet. If there was paint there before, there isn’t much left now due to the heat. I used 80 grit sandpaper to prepare the area for primer and new paint. If you aren't going for show quality, a wire brush would do. Whatever paint is left would be suspect so I used a sharp scraper to remove what was there. What is so cool about re-riveting this way is no-one will ever know and you will feel confident that you did it right!

If you did this right, the rivet looks just like any of the others on the truck and every bit as tight as they did it at the factory. I hope this helps someone and takes away a lot of the mystery. You can find other how-to articles right here at devestechnet.com. Join the discussion forums too!

Disclaimer: Be Careful Out There! Please whatever you do, wear safety goggles, gloves and follow all safety precautions concerning open flames, pressurized tanks, etc.

More Pictures available at The Site Archive Page

This article was first published at DevesTechNet.com (c)2015 All Rights Reserved

This procedure was done in the frame off configuration. It would be very difficult to do this on a complete truck due to the fire hazard. Observe all safety precautions and use common sense.

First off, the good news. It’s not all that hard! The hardest part of this entire thing was getting good information to figure out where to begin. Different procedures, different opinions abound. So after a very large amount of research, asking seemingly stupid questions on various forums, this is what actually works! I do not give website links in this procedure because they change. Do the appropriate Google Search! Where the opinions vary is a lot of the old timers used the boiler rivet method where you heat the whole rivet red hot, insert it in the hole and with a bucker (person) on one end holding a very heavy bucking bar, the other one hammers the rivet home. They insist this is the only way to get the proper heat throughout the rivet. I contend, after researching this, that by the time you have put the tongs on the hot rivet, pushed it in the hole, put the bar against it solidly you have cooled the head down sufficiently to the point where you might as well have just heated the rivet in the hole. The problem of heat shunting out due to the surrounding metal and bucking bar being cold IS a real problem. Maybe that’s why our friends at Chevy used hydraulic riveters and set them completely cold. I feel you can do it better because the rivet will tighten more as it cools.

First off, the good news. It’s not all that hard! The hardest part of this entire thing was getting good information to figure out where to begin. Different procedures, different opinions abound. So after a very large amount of research, asking seemingly stupid questions on various forums, this is what actually works! I do not give website links in this procedure because they change. Do the appropriate Google Search! Where the opinions vary is a lot of the old timers used the boiler rivet method where you heat the whole rivet red hot, insert it in the hole and with a bucker (person) on one end holding a very heavy bucking bar, the other one hammers the rivet home. They insist this is the only way to get the proper heat throughout the rivet. I contend, after researching this, that by the time you have put the tongs on the hot rivet, pushed it in the hole, put the bar against it solidly you have cooled the head down sufficiently to the point where you might as well have just heated the rivet in the hole. The problem of heat shunting out due to the surrounding metal and bucking bar being cold IS a real problem. Maybe that’s why our friends at Chevy used hydraulic riveters and set them completely cold. I feel you can do it better because the rivet will tighten more as it cools. What you need:

What you need: At least a 4x Air Chisel/ Hammer. I used one with a .401 hole to accept the readily available rivet setter. I had one sitting in a drawer so didn't have to go out and buy one, but if you don't have one, get a good Ingersol or Chicago Pneumatic while you are at it. They make chisels for these units that very nicely cut sheet metal so there are other applications (excuses) for having this around the shop.

An 11/16” Rivet Setter with the .401 shank. This is what does the shaping of the squashed rivet to make it look like factory. They are around $30 each. The one you need for most of the rivets on this frame is the 11/16” round head version made for a 3/8” rivet. I got mine from Byler Rivet. The part number was SM50 430-12.

An OxyAcetylene Torch with a #4 Medium Rosebud (Heating) Tip.I didn't have this at all, So more research told me to get a Victor Setup. NOT a Victor STYLE, TYPE setup. In other words, no chinese knockoffs here. Its worth the extra money to get the appropriate gear. The Victor Performer Edge Medium Duty Kit cost $230 on Amazon and the regulators and everything are excellent quality. If you are a noob, you will also need bottles. Your local welding supply can provide them at reasonable cost. Don’t play with fire! Get good OA Torch equipment because of the fire hazard and possible leakage from inferior tooling.

An OxyAcetylene Torch with a #4 Medium Rosebud (Heating) Tip.I didn't have this at all, So more research told me to get a Victor Setup. NOT a Victor STYLE, TYPE setup. In other words, no chinese knockoffs here. Its worth the extra money to get the appropriate gear. The Victor Performer Edge Medium Duty Kit cost $230 on Amazon and the regulators and everything are excellent quality. If you are a noob, you will also need bottles. Your local welding supply can provide them at reasonable cost. Don’t play with fire! Get good OA Torch equipment because of the fire hazard and possible leakage from inferior tooling.1-1/8 Inch Long, 3/8” shank diameter, Round Head, Steel Rivets.I got my rivets from Jay-Cee Rivets. 100 of them cost about $15. (Smallest quantity they sell). For those who are wondering why 1-1/8” long... I chose to get 100 of the same size and then cut them down to the appropriate size after I got them. The longest application is when you are riveting the front leaf spring mounts together with the rear engine crossmember. The rule for the length you need is 1.5 times the shank size sticking out of the hole. So you have a 3/8” rivet, you want the thickness of what you are riveting plus 3/8” plus 3/16” (half of the 3/8”) or to make a long story short, 9/16” sticking out of the hole. This works flawlessly and provides a very factory looking rivet. The part number was S0375R01125.

Bucking Bars. Go to your local welder and ask for scraps of 1/2” thick steel. You want the dimensions to vary but I used 1-1/2” by 8 inch for most of the job and a 2” by 10 inch for the rest. Read the rest of this procedure before doing this so you understand the concept first. You will be clamping this bar in place to hold the rivet, so you will also need to drill a 9/16” concave into the steel where the rivet will be placed. Put the bar against the hole and mark the hole, then drill the hole. Make the hole ONLY deep enough to complete a full circle with the tip of the drill bit. You just need a very slight but complete concavity.

Bucking Bars. Go to your local welder and ask for scraps of 1/2” thick steel. You want the dimensions to vary but I used 1-1/2” by 8 inch for most of the job and a 2” by 10 inch for the rest. Read the rest of this procedure before doing this so you understand the concept first. You will be clamping this bar in place to hold the rivet, so you will also need to drill a 9/16” concave into the steel where the rivet will be placed. Put the bar against the hole and mark the hole, then drill the hole. Make the hole ONLY deep enough to complete a full circle with the tip of the drill bit. You just need a very slight but complete concavity.

Anything more will change the appearance of the rivet head when finished. Another contributor pointed out that the entire rivet head is about 11/16 and if you shape that hole a little bigger and a little deeper you won’t have as much of a problem with the C-Clamps failing. Don’t make the hole too deep or the rivet won't tighten down. Also, the reason I chose 1/2” steel is because of some of the tight places, but if you can get thicker steel, the more mass the easier it will be on the clamps.

C-Clamps. Use very beefy, very stout large C-Clamps for this. The biggest problem you are going to have is keeping that bar in place when hammering, so go overboard and get a few good Bessey welding clamps if you can afford it. Vise grip types will not do, cheap woodworking clamps won’t do. The Bessey 4800S or 7200S is good, but very expensive. If they are too pricey, just use really good C-Clamps and hope for the best.

C-Clamps. Use very beefy, very stout large C-Clamps for this. The biggest problem you are going to have is keeping that bar in place when hammering, so go overboard and get a few good Bessey welding clamps if you can afford it. Vise grip types will not do, cheap woodworking clamps won’t do. The Bessey 4800S or 7200S is good, but very expensive. If they are too pricey, just use really good C-Clamps and hope for the best.Some Way to Cut Your Rivets. I use a DeWalt Porta-Band with the Swag Offroad Table. I drilled a 3/8” hole in a stick that was approximately the thickness of the shortest rivet, then used washers as shown to adjust the depth. A clean hole is very important to the end result as well. Make sure there is no paint, rust, crud inside or near the hole.

Now for the fun part!

Make sure you have a pretty nice fit by placing the rivet in the hole just to check that its not binding, or too loose. A 1/32” or so looseness is fine, but in my case, someone torched the old rivets out and ruined the holes, so I had to go in and weld them shut and re-drill them. Don’t expect the rivets to be very tight in the hole. The procedure will squash them very nicely to the proper size. For these vintage frames, the 3/8” rivet is the most popular.

Step 1: Place the rivet, cut to the appropriate length as previously mentioned, into the hole. You can grab it with a pair of visegrips so it will stay there. You are placing the head in the most inaccessible place pointing outwards where you can get the hammer its best chance at a straight shot. You can’t come at this at an angle at all!

Step 2: Place your custom bucking bar over the head of the rivet and very securely clamp into place. The clamps shown are not good enough for this job but it was all I had. Later, after fighting the problem of them falling off, I went to the heavier duty clamps. These DO work, but not consistently. I can’t express enough the importance of a good clamp. The hammer hits with such force that what you THINK is tight enough, probably isn’t.

Step 3: Ensure you have the secured rivet sticking straight out of the hole and not at an angle. Once it is straight and very secure...

Step 4: Insert the Rivet Setter into the air hammer, connect it to a normal 90-125psi air supply and just pretend you are going to use it to ensure there are no obstacles in your way. You want a totally unobstructed means to hammer the rivet home and the rivet setter must be totally straight to get a nice rivet head. Once you are sure you can push the rivet straight... Note: While I can see one person doing this, it is nice to have two people. The reason being, one person heats the rivet and pulls the torch away, turns it off, etc, while the other hammers the rivet. The heat doesn't last long enough to heat, then mess around with turning off the torch and setting it down, pick up the gun and rivet. If you had some sort of torch stand that you could just quickly set it on, maybe one person could do it. Get a friend to help you. Its just safer that way.

Step 5: Fire up the Acetylene Torch and heat the rivet shank EVENLY. Go around the diameter a few times and sort of at the base of the rivet with the idea of getting the shaft as hot at the base as possible. I was lucky since my friend Gene is also the town blacksmith he knew how hot to get the rivets before they melted. They should be glowing red hot and not just a little. If they start to turn white, back off. You need all the heat that rivet can stand.

Apply heat as close to the rivet head and base as possible as well as the entire shaft for best results. By the way, you can’t be reading this and doing the procedure at the same time! You simply don’t have time! It takes about 10-15 seconds to heat the rivet.

Apply heat as close to the rivet head and base as possible as well as the entire shaft for best results. By the way, you can’t be reading this and doing the procedure at the same time! You simply don’t have time! It takes about 10-15 seconds to heat the rivet. Step 6: Speed is of the essence here. If you are a slow person, get someone else to do this. My friend Gene heated up the rivet, I stood right there beside the work with both hands on the gun and the very second he took the torch away, I hammered the rivet down. So be sure to have your rivet gun ready and place the rivet setter very squarely on the top of the red hot rivet and pull the trigger while pushing down. Push hard and straight until the rivet setting tool is almost completely against the frame. This takes about 2 seconds. Everything happens really fast.

Step 6: Speed is of the essence here. If you are a slow person, get someone else to do this. My friend Gene heated up the rivet, I stood right there beside the work with both hands on the gun and the very second he took the torch away, I hammered the rivet down. So be sure to have your rivet gun ready and place the rivet setter very squarely on the top of the red hot rivet and pull the trigger while pushing down. Push hard and straight until the rivet setting tool is almost completely against the frame. This takes about 2 seconds. Everything happens really fast.

Step 7: Admire your work. My first attempt was perfect and the rivet looked amazing. My second attempt wasn't so pretty so I had to grind off the rivet head and start all over. This turned out to be very revealing anyway. There is some controversy about this procedure shunting all the heat into the bucking bar thus making for a less secure rivet. I assure you this isn’t the case. On close examination of the cross section, all of the hole was completely filled and it took a very large punch and a very big hammer to knock it out of the hole. Due to the properties of steel, heating a rivet, squashing it in the hole, then letting it cool makes for an extra tight fit since heat expands when hot and contracts when cool.

At this point all that’s left is cleaning around the rivet. If there was paint there before, there isn’t much left now due to the heat. I used 80 grit sandpaper to prepare the area for primer and new paint. If you aren't going for show quality, a wire brush would do. Whatever paint is left would be suspect so I used a sharp scraper to remove what was there. What is so cool about re-riveting this way is no-one will ever know and you will feel confident that you did it right!

If you did this right, the rivet looks just like any of the others on the truck and every bit as tight as they did it at the factory. I hope this helps someone and takes away a lot of the mystery. You can find other how-to articles right here at devestechnet.com. Join the discussion forums too!

Disclaimer: Be Careful Out There! Please whatever you do, wear safety goggles, gloves and follow all safety precautions concerning open flames, pressurized tanks, etc.

More Pictures available at The Site Archive Page

This article was first published at DevesTechNet.com (c)2015 All Rights Reserved

Welcome to Deves Technet.com Forums. I encourage everyone to register so we can get a better idea of the traffic and its usefulness. Please leave a word or two describing your stay and what we can do to make it more enjoyable. Thanks!

Welcome to Deves Technet.com Forums. I encourage everyone to register so we can get a better idea of the traffic and its usefulness. Please leave a word or two describing your stay and what we can do to make it more enjoyable. Thanks!