After looking over the fuel sender, I decided to test it out on an actual 1950 Chevy Truck gauge set. This one hasn't been converted to 12 volts, so let's take the time to discuss the options on reducing the gauge voltage to 6 volts using a 12 volt power source. I will explain a fourth option and the best option in the "Going Native" article, but for now, let's explore the normal gauge voltage reduction process. The sending unit is not affected at all. The only part of the fuel gauge system that is affected is the power connection. A few words on the sender first...

The sender is a 0-30 ohm sender with 0 being empty and 30 being full. In order to create this ohm value system, roughly 2 volts are sent through the sending line. In the tests I did recently, 2.1 volts/30 ohms means a full tank and 100 millivolts/0 ohms means an empty tank. This enables us to tell almost exactly how much gas is in the tank.

The gauge reduction process is about the same as reducing the heater fan motor with a few differences. The first one being, the gauge set uses much less current and only 5 watt power rating reduction is required. There are three basic ways we will discuss here on how to reduce your gauges.

1) The 5 watt 1.5 Ohm Power Resistor

2) The Solid State (Runtz) Solution

3) The 6.8 Volt, 5 watt Zener Diode

The 5 watt 1.5 Ohm Power Resistor is the mainstay and is used for gauges a lot. There is nothing wrong with using them and they have mounting holes so you can mount them out of the way somewhere on Metal so it acts as a heat sink. It gets hot, but not excessively considering what you are doing.. turning half of your voltage into heat. The 25 Watt version is shown here, but the 5 watt is much smaller and perfect for this application.

The Solid State Solution mounts to the existing terminal connection and doesn't require you to find a place to mount it. It is small and pretty well designed, I just question the need for all of the solid state components. Reducing voltage to a gauge is not where I would think to put transistors, capacitors and diodes. This one gets just as hot as the Resistor, so I am not seeing an upside.

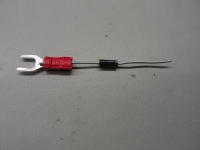

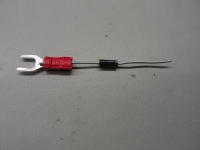

The 6.8 Volt, 5 watt Zener Diode is a passive device just like the resistor and acts much the same way. It has about the same longevity as the resistor and there are no circuits to break down over time. I find this to be the best solution because you can put a screw lug terminal on one end of it, and the wire on the other, cover it in shrink tubing and place it right at the gauge. For about .58 cents each, I don't see any downside other than it also gets as hot as the resistor. The heat isn't terrible, but it's noticeable.

There are other versions of reducers that work too, but these are the most common. They all work by turning half of your voltage into heat which is then dissipated from the ambient temperature. In any case, the sending part of the circuit is not affected by the voltage reduction.

What we won't talk about until I actually do the research is the 12 volt Native solution. This is retrofitting the gauge set with actual 12 volt innards so there is no reduction process needed. Of course this is the best way to go because you are not turning half of your voltage into heat.

The sender is a 0-30 ohm sender with 0 being empty and 30 being full. In order to create this ohm value system, roughly 2 volts are sent through the sending line. In the tests I did recently, 2.1 volts/30 ohms means a full tank and 100 millivolts/0 ohms means an empty tank. This enables us to tell almost exactly how much gas is in the tank.

The gauge reduction process is about the same as reducing the heater fan motor with a few differences. The first one being, the gauge set uses much less current and only 5 watt power rating reduction is required. There are three basic ways we will discuss here on how to reduce your gauges.

1) The 5 watt 1.5 Ohm Power Resistor

2) The Solid State (Runtz) Solution

3) The 6.8 Volt, 5 watt Zener Diode

The 5 watt 1.5 Ohm Power Resistor is the mainstay and is used for gauges a lot. There is nothing wrong with using them and they have mounting holes so you can mount them out of the way somewhere on Metal so it acts as a heat sink. It gets hot, but not excessively considering what you are doing.. turning half of your voltage into heat. The 25 Watt version is shown here, but the 5 watt is much smaller and perfect for this application.

The Solid State Solution mounts to the existing terminal connection and doesn't require you to find a place to mount it. It is small and pretty well designed, I just question the need for all of the solid state components. Reducing voltage to a gauge is not where I would think to put transistors, capacitors and diodes. This one gets just as hot as the Resistor, so I am not seeing an upside.

The 6.8 Volt, 5 watt Zener Diode is a passive device just like the resistor and acts much the same way. It has about the same longevity as the resistor and there are no circuits to break down over time. I find this to be the best solution because you can put a screw lug terminal on one end of it, and the wire on the other, cover it in shrink tubing and place it right at the gauge. For about .58 cents each, I don't see any downside other than it also gets as hot as the resistor. The heat isn't terrible, but it's noticeable.

There are other versions of reducers that work too, but these are the most common. They all work by turning half of your voltage into heat which is then dissipated from the ambient temperature. In any case, the sending part of the circuit is not affected by the voltage reduction.

What we won't talk about until I actually do the research is the 12 volt Native solution. This is retrofitting the gauge set with actual 12 volt innards so there is no reduction process needed. Of course this is the best way to go because you are not turning half of your voltage into heat.

Welcome to Deves Technet.com Forums. I encourage everyone to register so we can get a better idea of the traffic and its usefulness. Please leave a word or two describing your stay and what we can do to make it more enjoyable. Thanks!

Welcome to Deves Technet.com Forums. I encourage everyone to register so we can get a better idea of the traffic and its usefulness. Please leave a word or two describing your stay and what we can do to make it more enjoyable. Thanks!

Comment