This week we will squash once and for all a deficiency in the Factory Assembly Manual that will come to haunt you sooner or later in the restoration process. The problem comes when you go to install your running boards and you discover the bolt holes between the running board brackets and the frame mount do not line up. The most common problem arises from a bent frame mount. As beefy as they are, they DO get bent. If more than one gets bent, you have no reference to determine how to bend them back. If you are using donor running boards, maybe the guy who replaced the running board brackets that are spot welded to the running boards were placed wrong?

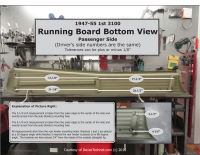

This week we will squash once and for all a deficiency in the Factory Assembly Manual that will come to haunt you sooner or later in the restoration process. The problem comes when you go to install your running boards and you discover the bolt holes between the running board brackets and the frame mount do not line up. The most common problem arises from a bent frame mount. As beefy as they are, they DO get bent. If more than one gets bent, you have no reference to determine how to bend them back. If you are using donor running boards, maybe the guy who replaced the running board brackets that are spot welded to the running boards were placed wrong? The biggest issue isn't apparent until you go to installing the rear fenders since the running board is mounted directly to it. Too far forward or too far back by just a smidge and you have a big problem. Yes, those running boards need to be within 1/8" of placed perfectly or bad problems start to arise. The Factory Assembly Manual is of no help so last week I started researching this problem and this is what I found. I will not bore you with a bunch of numbers in the text here, just click on the picture on the right and it tells the whole story.

The biggest issue isn't apparent until you go to installing the rear fenders since the running board is mounted directly to it. Too far forward or too far back by just a smidge and you have a big problem. Yes, those running boards need to be within 1/8" of placed perfectly or bad problems start to arise. The Factory Assembly Manual is of no help so last week I started researching this problem and this is what I found. I will not bore you with a bunch of numbers in the text here, just click on the picture on the right and it tells the whole story.Now you can build your running boards with confidence. Taking off the old rusted running board brackets is easy. Remove a few spot welds, sandblast or clean the area, then weld in new ones. Be sure to follow the instructions on placement carefully by making several measurements per the instruction in the picture. A good idea is to print out that large picture with the instruction and slide it into the FAM for future reference. Seeya Next Week!

Welcome to Deves Technet.com Forums. I encourage everyone to register so we can get a better idea of the traffic and its usefulness. Please leave a word or two describing your stay and what we can do to make it more enjoyable. Thanks!

Welcome to Deves Technet.com Forums. I encourage everyone to register so we can get a better idea of the traffic and its usefulness. Please leave a word or two describing your stay and what we can do to make it more enjoyable. Thanks!