For the Fifty Third Tip of the Week, I wanted to celebrate a year of doing this with a really good one. Yes, they can be rated. Some are better than others. This is one that should be of interest to all of you. Unless you are a Corn Farmer with definite interest in keeping the Ethanol train going, it is an irrefutable fact that Ethanol in gasoline shortens the life of the gas sitting in your tank over time. Every lawn mower manufacturer in the world has a warning that indicates that if you leave your gas in the tank longer than THIRTY DAYS you should use a treatment chemical like STABIL in the tank to prevent damage to your fuel system. This is way different than it has ever been. We used to be able to let gas sit in the tank for a year or more. NOT anymore! Even if you disagree, the truth is, it is doing damage to certain parts of your engine. In this Tip of the Week we are focusing on Fuel Pumps. The mechanical fuel pump diaphragm is made out of a rubber that is very sensitive to ethanol. Your mechanical fuel pump just won't last as long if you insist on using Ethanol in your fuel. I would also introduce there is anecdotal evidence that mechanical fuel pumps are not as reliable as they used to be. I know from experience that a mechanical fuel pump may last 5 years, or it may last 1. You just never know when it will leave you stranded. This of course can be said for many of our 65 year old parts, but there IS something we can do about this one. Enter the Electric Fuel Pump. But how do they work? Why are they different? What do they cost? Are they more efficient and reliable?

Electric Fuel Pumps work similar to the mechanical ones in that they PULSE fuel through the system. The diaphragm that pushes the fuel through the system is smaller and the pump is OEM so it has been engineered for modern fuels. Electric Fuel Pumps work exactly the same in the vehicle's fuel system as the mechanical ones do. When sufficient fuel is pumped into the Carburetor to bring the Carburetors float to maximum, the fuel pump stops pumping. This is because the Carburetors float valve is stronger than the 4-5 psi the Pump is rated to push through. Same as the Mechanical Pump. If you have ever wondered what stops a fuel pump from pumping its maximum fuel into your engine, it is the Carburetors float valve that does that. The ONLY difference between a Mechanical and an Electric Fuel Pump is its method of providing energy to power it. Mechanical uses a lever that rides on the Engines Camshaft. Since it is concentric (cam based), it works as a pump. Electric Pumps (the affordable ones) are electronically set to Pulse the output to emulate the mechanical pumps action. So I hope this gives you more confidence in Electric Fuel Pumps. But we are not done answering your questions yet....

One of the advantages of the Mechanical Fuel Pump is that when the engine stops, so does the fuel pump. It is not an optional thing, it STOPS DEAD. This is a safety issue and one that we want our Electric Counterpart to also do very reliably. Another thing we want is for our electric pump to emulate the mechanical one precisely. We want to listen and adhere to GM engineers fuel flow requirements as put out when your engine was brand new. So now let's talk statistics...

The original 1958 235/261 Mechanical Fuel Pump has two important ratings. One is Maximum Gallons Per Hour (gph). The stock mechanical one is rated at 25 gph. Meaning, the MOST you will ever consume in Gas during one hour is 25 gallons. The other stat that is important is the Fuel Pressure. Fuel Pressure for the stock mechanical pump is rated at a minimum of 3.5 and a maximum of 4.5 pounds per square inch (psi). This is well under the Carburetors float shut-off valve's ceiling.

Our Electric fuel pump choice must have the same statistics so that we are able to fool the Carburetor into thinking it is getting its normal fuel flow. If we can pull that one off, we have one other hurdle. We need to make this pump stop when the engine stops. This is done with an electrical Oil Pressure Sensor Switch. Most of us already use a mechanical oil pressure setup which is a small diameter copper line that goes directly to the Oil Pressure Gauge for measurement. We will not mess with that, we will add a 1/8" NPT FMF Tee Connector where the gauge is connected at the engine block and then install an electrical additional sensor/switch to the mix. Here's why that is actually a good thing...

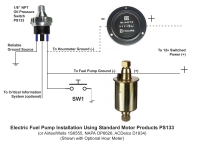

The three prong Standard Motor Products PS133 Oil Pressure Switch brings a few capabilities to the table that your vehicle didn't have before. Here are a few of the possibilities:

1) Allows you to connect a CIS System to your vehicle.

2) Gives you the ability to connect a very accurate Hour Meter to your Engine.

3) Allows you to connect an Electric Fuel Pump.

4) All of the above if you choose.

The diagram shows how to make this happen. The two terminals across from each other only 'switch' together (make/break) once oil pressure is reached. By connecting it strategically, we can ensure the fuel pump and/or Hour Meter stops when the Engine does. The center terminal is together when NO Oil Pressure is present (opposite of the other two) allowing for the CIS system to work as advertised. This enables our Electric Fuel Pump to emulate EXACTLY the Mechanical counterpart.

So, all we have to do now is find an Electric Fuel Pump that puts out the same GPH and PSI that the Mechanical one does. Here are a few choices. If you find others, please let me know.

Airtech Model E8251 - This one will put out 30 gallons per hour, and max PSI is 4.5. Since the Carb is what governs the fuel flow, 30 gallons is just fine. This does not mean you will be using more fuel, it just means the pump is capable of it. Since this is an OEM product, it is manufactured by Carter (Part Number P74021) and Spectra Premium (Part Number SP1170) and they are all three identical.

Holley Mitey Mite Part Number 12-426 - This one puts out 25 gallons per hour and max PSI is 4. This one falls exactly within our target but is not OEM. We don't care much, but OEM means the pump is routinely used in the manufacturing of vehicles. This one is aftermarket only. Still works fine.

Facet/Purolator PRO87SV - It puts out 32 gallons per hour and a max of 5 PSI. This one has a built in filter which if available is a great thing, but so far I have only been able to source this one through Ebay which is a Red Flag for me because it reduces its guarantee of future availability. Also not OEM.

All of the above use a 1/8-27 thread size (considered 5/16 for barb size purposes) and allow you to use either Barbs and flex rubber hose, or make it more permanent with hard lines using flare fittings.

A few other interesting facts is the electric pump should be attached to your Ignition Switch and uses about 3-5 amps of current. A 10 amp fuse will work great using 14 gauge hookup wire. Follow the schematic and enjoy a very reliable fuel system. Of course nothing is foolproof, but ask yourself why ALL car manufacturers went to Electric years ago. The Electric solution is considered more reliable and another thing to not have to concern yourself with when you start your engine! I am not sure if engine performance is increased in removing the mechanical pump or not.

Also, let's not forget we need to address the hole in the engine block that used to accommodate the mechanical fuel pump. This of course if you choose to remove the mechanical one. Take a mechanical fuel pump gasket and trace around it on a nice piece of 14 gauge Stainless Steel! Drill the appropriate 5/16" holes, add a few stainless bolts and hardware and some gasket sealer, and you have really done things in style!

But Wait! There is MORE!

After discussing this project with many sources, you will get opinions that vary about the Electric Pumps reliability. Is it REALLY more reliable than the Mechanical Pump? Well, let's take that issue out of the equation and show you how to AUGMENT the fuel flow and connect BOTH pumps. What this does is give you a backup. Electric one dies, fuel still gets there. Mechanical one dies, fuel still gets there. They do this on Airplanes as a matter of routine, so why not? But WHY is more interesting! Do you have a vehicle that if left sitting a few days (or longer) means harder starting because you have to wait for the Carburetors fuel bowl to fill again? Most of us do.

Why not wire the Electric Pump that you are using to Augment your Mechanical one so that it Primes the Carb before starting? That is what SW-1 in the diagram above is for! The switch, SW-1 in the schematic is a Momentary ON switch. Put that one somewhere near the choke inside the vehicle. This switch when depressed for about 5 seconds will prime the carburetor for those who want that feature. The one minor thing is when you depress the switch, your hour meter (if installed) will count the time you depress it, but it's such a small variance it is hardly worth mention.

Installation is up to you, but I would put the Electric Pump on the frame rail. The fuel line from the Tank to an inline fuel filter, then the electric pump, then the mechanical pump on up to the Carb. Of course remember to make maintenance easier, put a nice fuel filter before any pumps and make it accessible. Having a filter before any pumps will extend pump life considerably. I am not letting this one go because I see an opportunity for a few different Kits, so check the Farm-It-Out page from time to time.

NOTE: There is a more modern solution to the oil pressure sensor available to stop the pump from working in case of a rollover/accident. It is called a Fuel Pump Inertia Switch such as the Airtech-Wells SW4177. This would eliminate the need for the oil pressure sensor and the SW-1 switch in the diagram because the pump would activate on ignition startup. It sounds like a good idea, but the cost for a new one is about $60. I am still researching this problem and am hopeful we can come up with a more cost effective solution. In addition to cost, it has been mentioned that the carbs float valve is a wear item and maybe we do not want the electric pump all the time the ignition is turned on. This makes the original schematic look more attractive. It would be nice however to have an automatic priming feature in the circuit so more to come.

Electric Fuel Pumps work similar to the mechanical ones in that they PULSE fuel through the system. The diaphragm that pushes the fuel through the system is smaller and the pump is OEM so it has been engineered for modern fuels. Electric Fuel Pumps work exactly the same in the vehicle's fuel system as the mechanical ones do. When sufficient fuel is pumped into the Carburetor to bring the Carburetors float to maximum, the fuel pump stops pumping. This is because the Carburetors float valve is stronger than the 4-5 psi the Pump is rated to push through. Same as the Mechanical Pump. If you have ever wondered what stops a fuel pump from pumping its maximum fuel into your engine, it is the Carburetors float valve that does that. The ONLY difference between a Mechanical and an Electric Fuel Pump is its method of providing energy to power it. Mechanical uses a lever that rides on the Engines Camshaft. Since it is concentric (cam based), it works as a pump. Electric Pumps (the affordable ones) are electronically set to Pulse the output to emulate the mechanical pumps action. So I hope this gives you more confidence in Electric Fuel Pumps. But we are not done answering your questions yet....

One of the advantages of the Mechanical Fuel Pump is that when the engine stops, so does the fuel pump. It is not an optional thing, it STOPS DEAD. This is a safety issue and one that we want our Electric Counterpart to also do very reliably. Another thing we want is for our electric pump to emulate the mechanical one precisely. We want to listen and adhere to GM engineers fuel flow requirements as put out when your engine was brand new. So now let's talk statistics...

The original 1958 235/261 Mechanical Fuel Pump has two important ratings. One is Maximum Gallons Per Hour (gph). The stock mechanical one is rated at 25 gph. Meaning, the MOST you will ever consume in Gas during one hour is 25 gallons. The other stat that is important is the Fuel Pressure. Fuel Pressure for the stock mechanical pump is rated at a minimum of 3.5 and a maximum of 4.5 pounds per square inch (psi). This is well under the Carburetors float shut-off valve's ceiling.

Our Electric fuel pump choice must have the same statistics so that we are able to fool the Carburetor into thinking it is getting its normal fuel flow. If we can pull that one off, we have one other hurdle. We need to make this pump stop when the engine stops. This is done with an electrical Oil Pressure Sensor Switch. Most of us already use a mechanical oil pressure setup which is a small diameter copper line that goes directly to the Oil Pressure Gauge for measurement. We will not mess with that, we will add a 1/8" NPT FMF Tee Connector where the gauge is connected at the engine block and then install an electrical additional sensor/switch to the mix. Here's why that is actually a good thing...

The three prong Standard Motor Products PS133 Oil Pressure Switch brings a few capabilities to the table that your vehicle didn't have before. Here are a few of the possibilities:

1) Allows you to connect a CIS System to your vehicle.

2) Gives you the ability to connect a very accurate Hour Meter to your Engine.

3) Allows you to connect an Electric Fuel Pump.

4) All of the above if you choose.

The diagram shows how to make this happen. The two terminals across from each other only 'switch' together (make/break) once oil pressure is reached. By connecting it strategically, we can ensure the fuel pump and/or Hour Meter stops when the Engine does. The center terminal is together when NO Oil Pressure is present (opposite of the other two) allowing for the CIS system to work as advertised. This enables our Electric Fuel Pump to emulate EXACTLY the Mechanical counterpart.

So, all we have to do now is find an Electric Fuel Pump that puts out the same GPH and PSI that the Mechanical one does. Here are a few choices. If you find others, please let me know.

Airtech Model E8251 - This one will put out 30 gallons per hour, and max PSI is 4.5. Since the Carb is what governs the fuel flow, 30 gallons is just fine. This does not mean you will be using more fuel, it just means the pump is capable of it. Since this is an OEM product, it is manufactured by Carter (Part Number P74021) and Spectra Premium (Part Number SP1170) and they are all three identical.

Holley Mitey Mite Part Number 12-426 - This one puts out 25 gallons per hour and max PSI is 4. This one falls exactly within our target but is not OEM. We don't care much, but OEM means the pump is routinely used in the manufacturing of vehicles. This one is aftermarket only. Still works fine.

Facet/Purolator PRO87SV - It puts out 32 gallons per hour and a max of 5 PSI. This one has a built in filter which if available is a great thing, but so far I have only been able to source this one through Ebay which is a Red Flag for me because it reduces its guarantee of future availability. Also not OEM.

All of the above use a 1/8-27 thread size (considered 5/16 for barb size purposes) and allow you to use either Barbs and flex rubber hose, or make it more permanent with hard lines using flare fittings.

A few other interesting facts is the electric pump should be attached to your Ignition Switch and uses about 3-5 amps of current. A 10 amp fuse will work great using 14 gauge hookup wire. Follow the schematic and enjoy a very reliable fuel system. Of course nothing is foolproof, but ask yourself why ALL car manufacturers went to Electric years ago. The Electric solution is considered more reliable and another thing to not have to concern yourself with when you start your engine! I am not sure if engine performance is increased in removing the mechanical pump or not.

Also, let's not forget we need to address the hole in the engine block that used to accommodate the mechanical fuel pump. This of course if you choose to remove the mechanical one. Take a mechanical fuel pump gasket and trace around it on a nice piece of 14 gauge Stainless Steel! Drill the appropriate 5/16" holes, add a few stainless bolts and hardware and some gasket sealer, and you have really done things in style!

But Wait! There is MORE!

After discussing this project with many sources, you will get opinions that vary about the Electric Pumps reliability. Is it REALLY more reliable than the Mechanical Pump? Well, let's take that issue out of the equation and show you how to AUGMENT the fuel flow and connect BOTH pumps. What this does is give you a backup. Electric one dies, fuel still gets there. Mechanical one dies, fuel still gets there. They do this on Airplanes as a matter of routine, so why not? But WHY is more interesting! Do you have a vehicle that if left sitting a few days (or longer) means harder starting because you have to wait for the Carburetors fuel bowl to fill again? Most of us do.

Why not wire the Electric Pump that you are using to Augment your Mechanical one so that it Primes the Carb before starting? That is what SW-1 in the diagram above is for! The switch, SW-1 in the schematic is a Momentary ON switch. Put that one somewhere near the choke inside the vehicle. This switch when depressed for about 5 seconds will prime the carburetor for those who want that feature. The one minor thing is when you depress the switch, your hour meter (if installed) will count the time you depress it, but it's such a small variance it is hardly worth mention.

Installation is up to you, but I would put the Electric Pump on the frame rail. The fuel line from the Tank to an inline fuel filter, then the electric pump, then the mechanical pump on up to the Carb. Of course remember to make maintenance easier, put a nice fuel filter before any pumps and make it accessible. Having a filter before any pumps will extend pump life considerably. I am not letting this one go because I see an opportunity for a few different Kits, so check the Farm-It-Out page from time to time.

NOTE: There is a more modern solution to the oil pressure sensor available to stop the pump from working in case of a rollover/accident. It is called a Fuel Pump Inertia Switch such as the Airtech-Wells SW4177. This would eliminate the need for the oil pressure sensor and the SW-1 switch in the diagram because the pump would activate on ignition startup. It sounds like a good idea, but the cost for a new one is about $60. I am still researching this problem and am hopeful we can come up with a more cost effective solution. In addition to cost, it has been mentioned that the carbs float valve is a wear item and maybe we do not want the electric pump all the time the ignition is turned on. This makes the original schematic look more attractive. It would be nice however to have an automatic priming feature in the circuit so more to come.

Welcome to Deves Technet.com Forums. I encourage everyone to register so we can get a better idea of the traffic and its usefulness. Please leave a word or two describing your stay and what we can do to make it more enjoyable. Thanks!

Welcome to Deves Technet.com Forums. I encourage everyone to register so we can get a better idea of the traffic and its usefulness. Please leave a word or two describing your stay and what we can do to make it more enjoyable. Thanks!

Comment