This week we are privileged to get handed a truly great Tip from our own Pre68Dave. It is obvious I am not the only one who writes about these trucks and we certainly welcome articles from all over the world. Thanks Dave!

As The Brake Drum Turns

In the early days when a brake drum was worn or scored it was turned oversize during a brake job. At the same time the shoes were arced with a machine that ground the lining surface so it matched the new contour of the oversize turned drum.

Because brake shoes were made with asbestos at the time, the EPA ended up banning the use of these arcing machines, as they put asbestos dust in the air. There are a few, but very few shops that will still arc shoes.

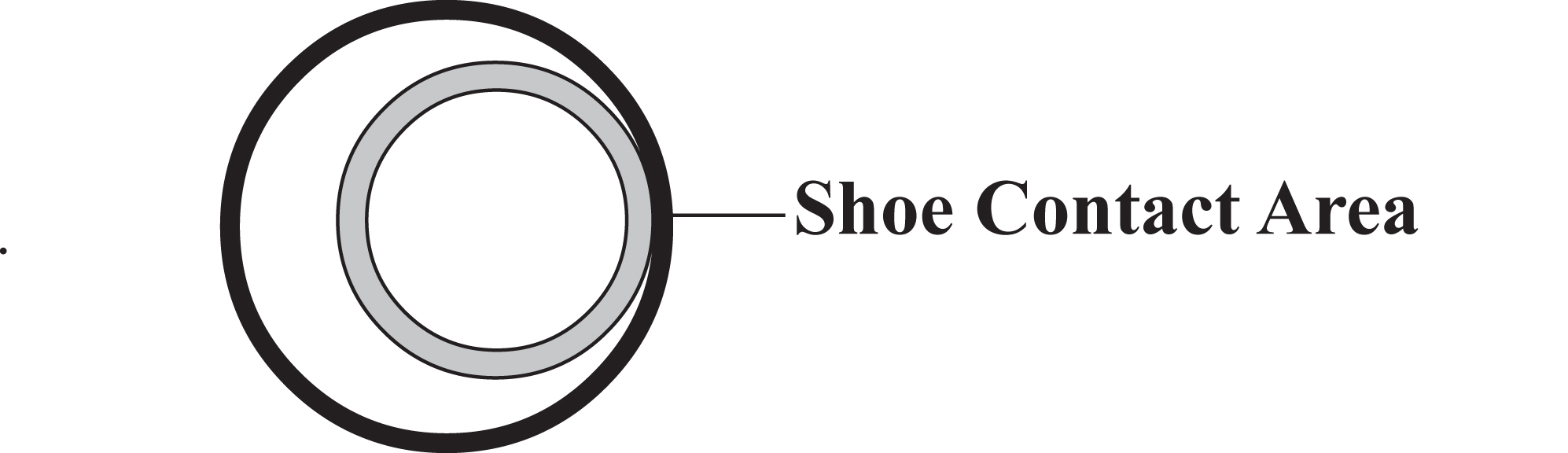

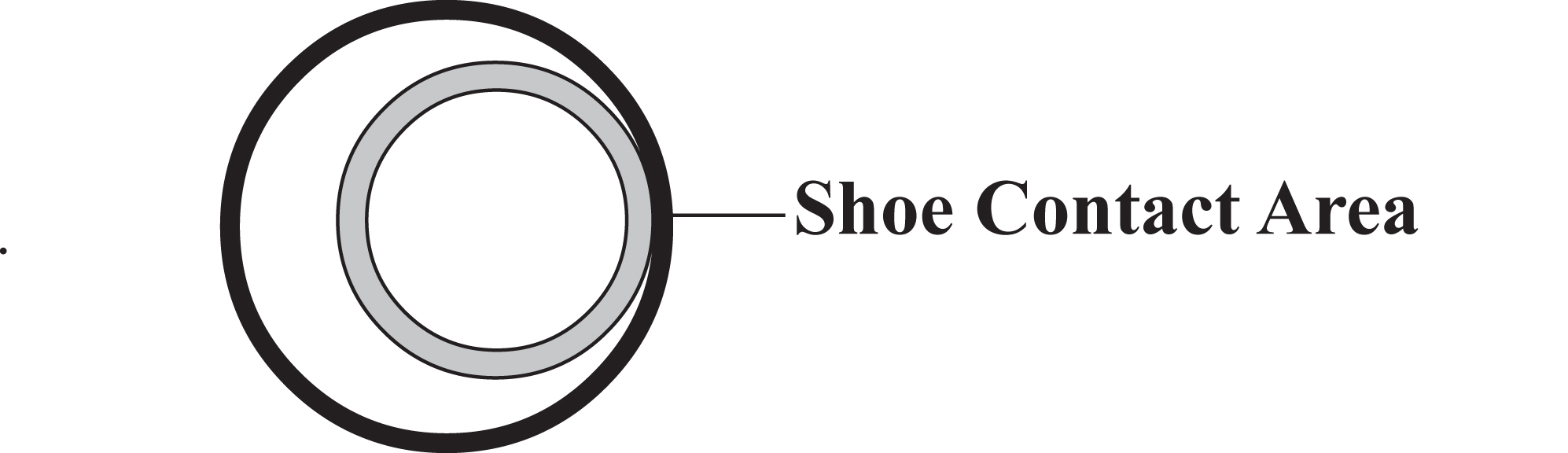

The resulting problem is that when a brake job is done where the drums are turned and the shoes are not re-arced you are left with a poor stopping job, as you ended up with reduced shoe to drum contact surface area (see diagram example).

In my exaggerated drawing you can see how a set of shoes designed for an 11†drum will only make surface contact on a very small part of the shoes.

In my exaggerated drawing you can see how a set of shoes designed for an 11†drum will only make surface contact on a very small part of the shoes.

There are a number of things to consider when it comes time to turn or not to turn drums. Most shops turn drums for two main reasons, first for you to help pay for their machine and second so they are not responsible for making a decision on their condition. In a lot of cases drums do not need to be turned. The Chevrolet shop manual even states that some minor drum scoring is not a problem.

Another thing one should consider is the fact that a lot of these early drums are no longer available and the turning process removes precious metal.

In my 1954 Chevrolet shop manual for example, it says if the drum is .010†oversize or less, there is no problem using standard un-arced shoes. This is because the shoes can flex a small amount and or wear in quick enough, giving full shoe to drum contact. Any drum larger than that and the shoes should be re-arced to match the oversize size of the drum. It also states that a drum should not be turned more than .060†oversize as it affects dissipation of heat and may cause distortion of drum.

The point of this article is to make you aware of the fact that turned drums can have a negative effect on your braking performance. So make sure you mic. your drums every time you do a brake job.

As The Brake Drum Turns

In the early days when a brake drum was worn or scored it was turned oversize during a brake job. At the same time the shoes were arced with a machine that ground the lining surface so it matched the new contour of the oversize turned drum.

Because brake shoes were made with asbestos at the time, the EPA ended up banning the use of these arcing machines, as they put asbestos dust in the air. There are a few, but very few shops that will still arc shoes.

The resulting problem is that when a brake job is done where the drums are turned and the shoes are not re-arced you are left with a poor stopping job, as you ended up with reduced shoe to drum contact surface area (see diagram example).

In my exaggerated drawing you can see how a set of shoes designed for an 11†drum will only make surface contact on a very small part of the shoes.

In my exaggerated drawing you can see how a set of shoes designed for an 11†drum will only make surface contact on a very small part of the shoes.There are a number of things to consider when it comes time to turn or not to turn drums. Most shops turn drums for two main reasons, first for you to help pay for their machine and second so they are not responsible for making a decision on their condition. In a lot of cases drums do not need to be turned. The Chevrolet shop manual even states that some minor drum scoring is not a problem.

Another thing one should consider is the fact that a lot of these early drums are no longer available and the turning process removes precious metal.

In my 1954 Chevrolet shop manual for example, it says if the drum is .010†oversize or less, there is no problem using standard un-arced shoes. This is because the shoes can flex a small amount and or wear in quick enough, giving full shoe to drum contact. Any drum larger than that and the shoes should be re-arced to match the oversize size of the drum. It also states that a drum should not be turned more than .060†oversize as it affects dissipation of heat and may cause distortion of drum.

The point of this article is to make you aware of the fact that turned drums can have a negative effect on your braking performance. So make sure you mic. your drums every time you do a brake job.

Welcome to Deves Technet.com Forums. I encourage everyone to register so we can get a better idea of the traffic and its usefulness. Please leave a word or two describing your stay and what we can do to make it more enjoyable. Thanks!

Welcome to Deves Technet.com Forums. I encourage everyone to register so we can get a better idea of the traffic and its usefulness. Please leave a word or two describing your stay and what we can do to make it more enjoyable. Thanks!